What’s in the beams

The beams of the 880, or any folding trimaran for that matter are under extremely high loads. Quite often under loaded conditions the load on the beams will be 3-5x the total boat weight. On the 880 the calculated max load on the beams is around 9,000kg.

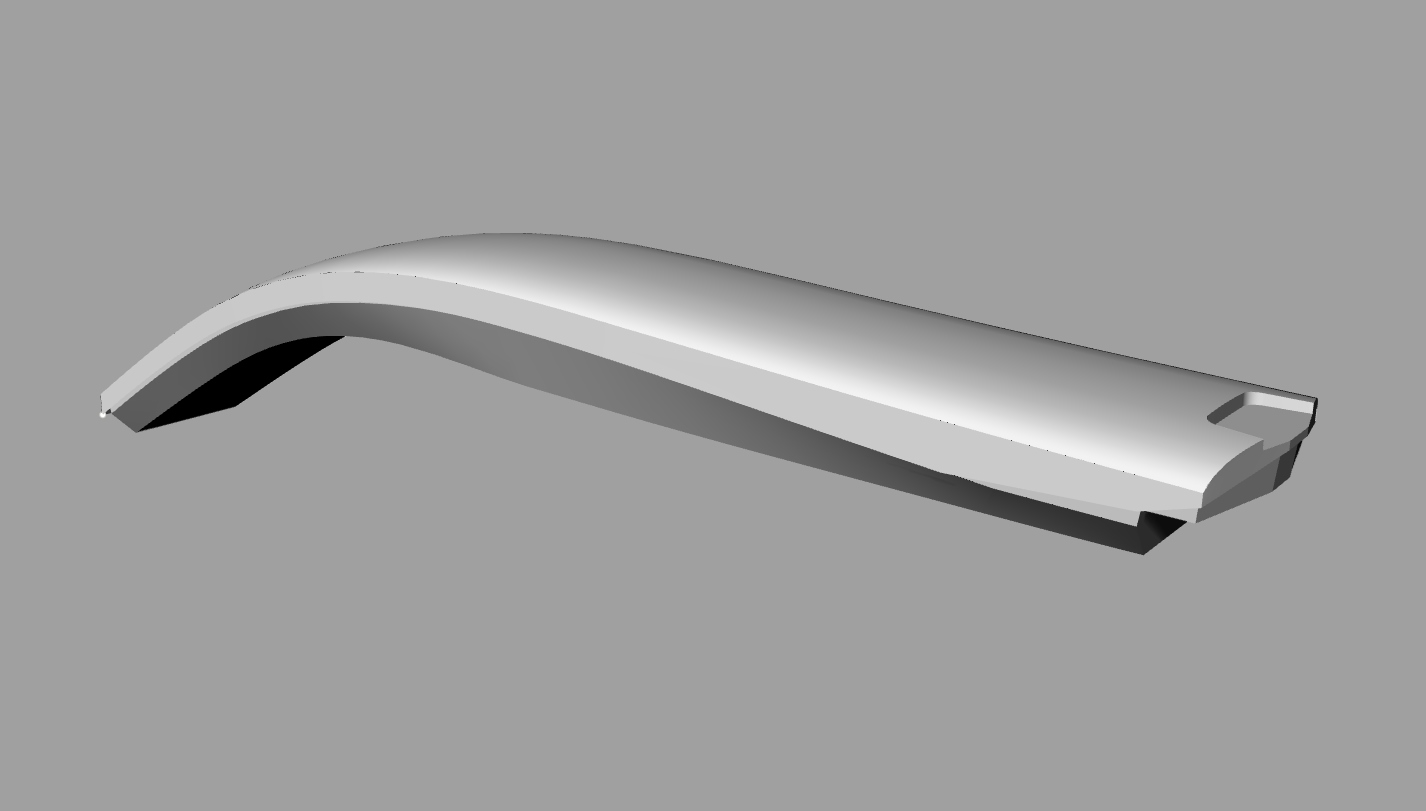

Corsair has years of experience building beams, and we understand the loaded requirements under all points of sail. We also understand the importance for a practical outcome, including considerations such as a safe walking surface and the benefits of creating a deflecting underside profile to minimize spray on the nets and cockpit.

During the early design stages of the 880, composite strut attachments were investigated as it was our initial intend to go in this direction. Extensive weight analysis identified little to no weight gains by using composite attachments. Furthermore the methods typically used for a composite attachment point actually hindered the folding geometry. Finally, given the results of our design testing and the extensive successful history of aluminum bracket attachments we identified this was the only logical way to proceed.

The attachment method was another area of much review and consideration. Throughout our trimaran range we use two methods of fixing beams to floats. Method a) involves bolting the beam ends to the upper surface of the float, this method is typically seen on our models of 28′ and under. Method b) incorporates an oversized beam end which is inserted inside of the float into a bulkhead and then glassed into place on arrival, you’ll see this on the 31’s, 970 and 37. Obviously method b is superior in strength, however is timely to assemble after delivery and somewhat permanent, making future shipments costly or difficult. Overcoming the weakness each of these options present for a boat of this size a hybrid solution was developed, providing both superior strength and ease of assembly. The solution incorporates a composite socket built into the float to accommodate each of the beams. The beams will be bolted in place however once underway the composite socket will actually do all the work of transferring the float loads onto the beams.

To manage and transfer the loads encountered when flying hulls, or even just in regular sailing conditions the beams have been designed with a centrally infused stringer. Using a technology found in the rear targa bar of Seawind Catamarans 1190 model, this stringer is infused in one hit as part of the infusion process of the upper and lower shells.

What is the Corsair 880? LEARN MORE>>

Sign up to receive more 880 development updates SIGN UP>>

Corsair Marine International Recognised at the Vietnam Top Brand Awards 2026

Corsair Marine International has been awarded at the Vietnam Top Brand Awards 2026, one of Vietnam’s most recognised national brand distinctions, honouring organisations that demonstrate strong brand credibility, consistent quality standards, and sustained contributions [...]

Why We Love Corsair 880

For many Corsair owners, the 880 represents more than a sailboat. It is the perfect balance between performance, comfort and pure sailing joy. In conversations with Dr. Michael Acker, a heart surgeon, and Engineer [...]

Corsair 880 Trimaran | Successful Australian Debut at the 2022 Sydney International Boat Show

Returning after 2 years of now shows due to Covid 19, the 2022 Sydney International Boat Show has brought the new breath to the boating community. Boating enthusiasts gathered for a weekend at ICC [...]

Corsair 880 Trimaran | 2022 Boat Review by Multihulls World

Corsair 880 - A brilliant toy for gliding across the water Corsair 880, a modern and ambitious trimaran that has a reputation to uphold: it is the new variation of the mythical Corsair F27, [...]

Corsair 880 – Drive Out, Fold Out, Thrill Out, Chill Out

Corsair 880 - Drive Out, Fold Out, Thrill Out, Chill Out Effortless performance is not a myth; it's the Corsair 880! The long-awaited new Corsair 880 brings new charisma to the 28ft folding trimaran [...]

Australian Debut of the Corsair 880 at the Sydney International Boat Show

We are thrilled to announce that the Corsair 880 Sport, our flagship, is making her Australian Debut at the 2022 Sydney International Boat Show! Corsair 880 out of Wareham Massachusetts “This is [...]

After countless destructive tests and design revisions we have now optomised the weight, strength, water deflection and style of the beam. It’s very easy to make something light, or to make it strong… but to optomize this balance has taken us a number of revisions in laminate and mold geometry. We are now happy to say we have nailed it. See below our current NDT quality controll tests which will be completed on every batch of 880 beams produced.