How do we ensure quality in our final design?

It’s a very good question, quality of the final molds is far more critical for a folding trimaran that pretty much any other boat design on the water. If the beam landings or strut mounts are out by a mere millimeter the entire folding geometry will be affected. So to overcome this risk we have employed a number of techniques to reduce the likelihood of tolerance issues and to catch them when they do occur.

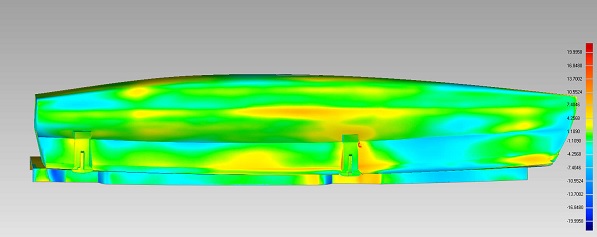

Firstly, in the construction of the components, we elected for cnc cut beam landings and strut mounts. This has ensured a sufficient accuracy of those hard to shape areas. These components have then been grafted into the traditionally framed plugs with careful precision and measurement. This was the first step to ensuring accuracy, the second was to check our work. So we have set up 3D scanners to scan and digitize all of the components. With an accurate digital file we were then able to overlay this with the original design and using specialized quality assurance software highlight deviations between the design file and the actual part. With this report the parts were then able to be finely tuned with precision before a final scan to confirm inaccuracies were within tolerance.

What is the Corsair 880? LEARN MORE>>

Sign up to receive more 880 development updates SIGN UP>>